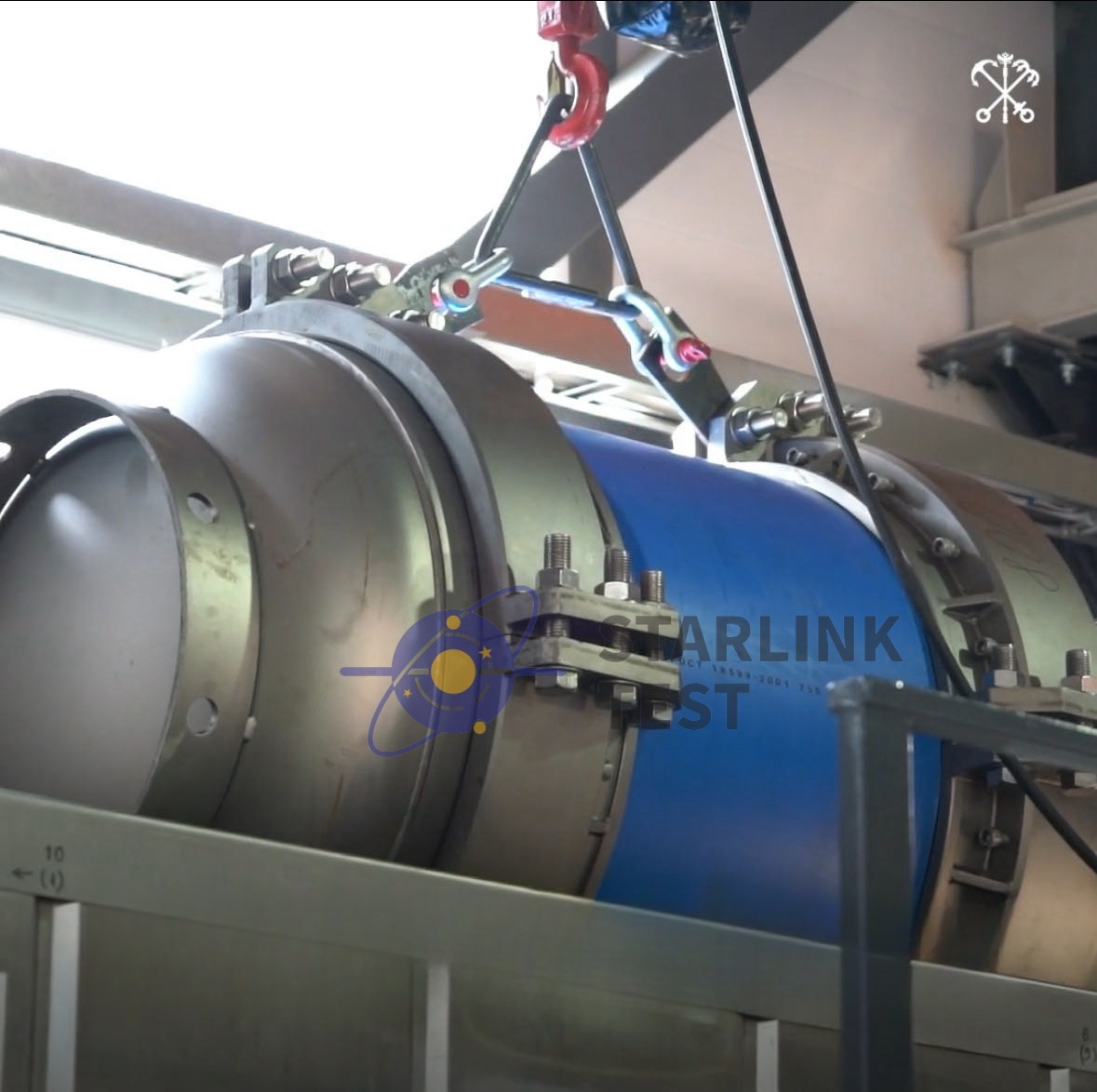

Plastic Pipe Testing Equipment

Notch Milling Machine

Model: SL-MT710

This instrument is an equipment for sample incision processing for the test method of resistance to slow crack growth and slow growth of thermoplastic pipes for fluid transportation.

Standard

ISO 13479《Polyolefin pipes for the conveyance of resistance to crack propagation-Test method for slow crack growth on notched pipes(notch test)》

Characters:

1) Fixing the sample using a pneumatic lifting mechanism.Multi-point type to support test piece, which ensures the parallelism between cutting knife and pipe and the repeatability of notch depth.

2) Automatic calculation of the cut depth based on the entered pipe diameter.

3) After processing one cut, the pipe can be electrically rotated 90° for the next cut. The pipe can be rotated in both forward and reverse directions, facilitating the observation of each cut's status.

4) Built-in monitoring system for the total length of machining by the milling cutter.

5) Human-machine interface for controlling the position and status of the milling cutter via a touchscreen.

6) It is possible to record and view the latest test records and data.

7) X and Y feeds adopt high-precision linear linear guides and high-precision ground ball screws, which have high cutting precision and ensure the validity of the test data for slow crack growth resistance.

Technical parameters:

1) Pipe diameter range: from 63 to 710 mm.

2) Maximum sample length: up to 1500 mm.

3) Notch length: from 50 to 720 mm.

4) Maximum machining depth: 20 mm.

5) Minimum wall thickness of the sample: 5 mm.

6) Diameter of the V-shaped cutter: 200 mm, 20 teeth, rotational speed: 700 RPM (adjustable).

7) Feed speed: from 140 to 940 mm/min.

8) Power supply: 220 V, 50 Hz, 2 kVA.

Click to download the complete content